paper plastic composite bags

Description

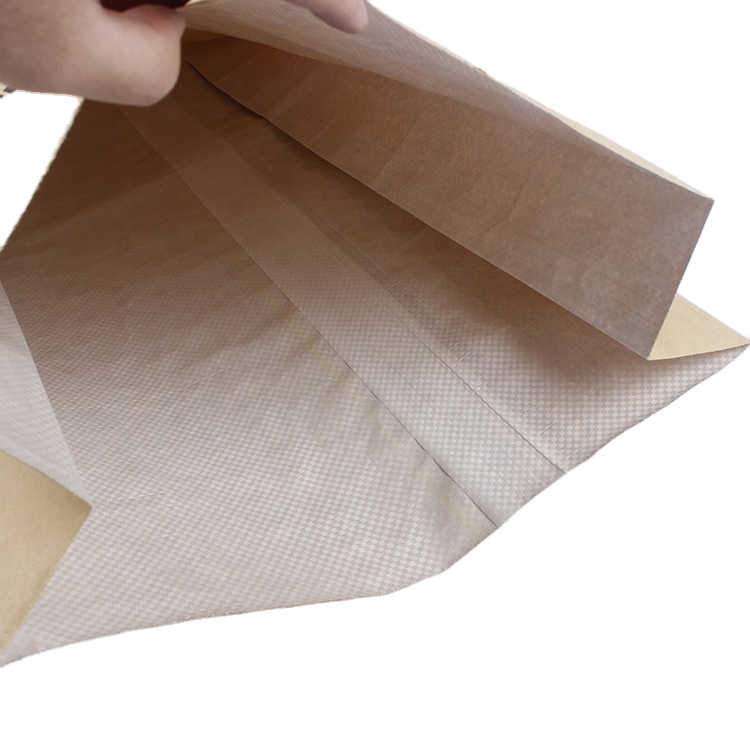

Paper-poly Kraft, also known as paper laminated or paper woven, are combination bags constructed with a paper shell laminated to a woven polypropylene inner-lining. The lining safeguards the contents from moisture, making it an ideal bag for holding grains, seeds, pet foods, flour, rice, sugar, fertilizers, frozen products, some chemicals and various building materials. Though the bags have a similar appearance and texture to standard multiwall paper bags, they offer extra strength, durability, protection from punctures or tears and higher moisture resistance.

The exterior paper comes in natural Kraft or bleached white. The inner layer of woven polypropylene is laminated to the paper by using a PE coating, making them one of the most durable bags on the market.

Customizing Options

-Unbleached Kraft Paper (brown color)

-Paper tape stitching |

|

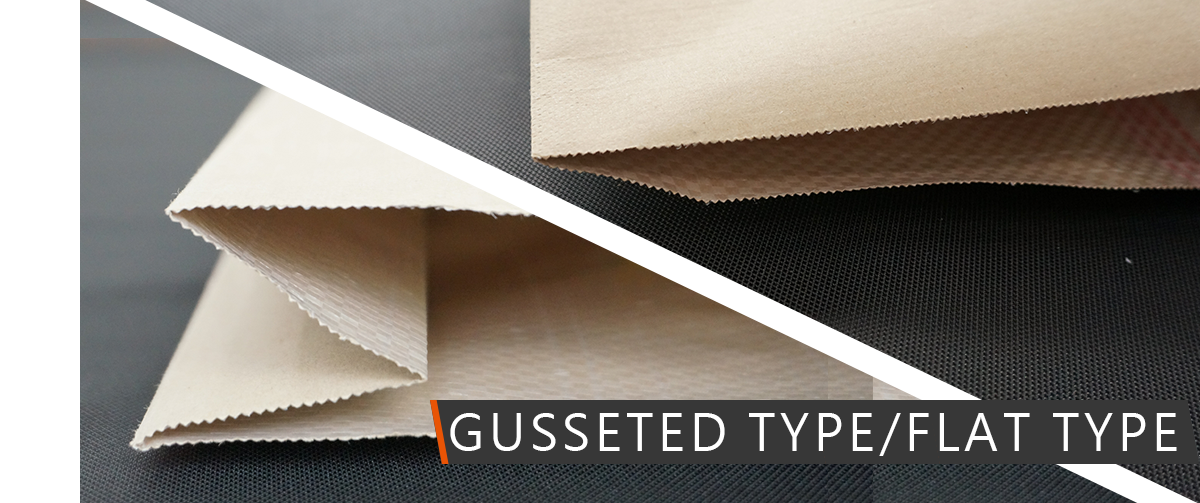

1.Bag Type

Flat type / Gusseted type

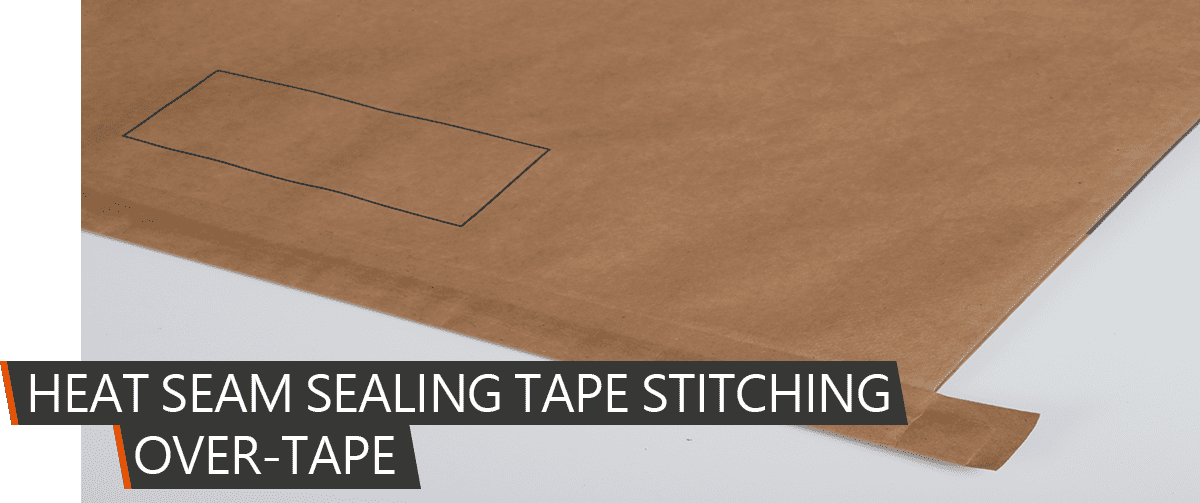

2.Paper tape stitching

By using high strength polyester cotton threads to increase load capacity.

3.Heat Seam Sealing Tape Stitching(Over-Tape)

Heat seam sealing tapes are multilayered adhesive

films applied to the polyester cotton thread-sewn

seams to prevent water from leaking through those

seams. This creates a seamless exterior.

4.Kraft Paper Option

Unbleached Kraft Paper (brown color) / Bleached Kraft Paper (white color) / Recycled Kraft Paper

are made from northern bleached softwood kraft (NBSK) pulp.

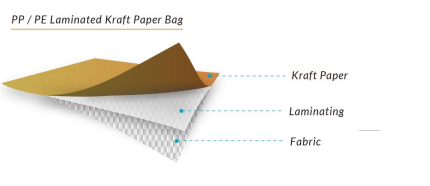

5.Structure

Kraft Paper Bags laminated with polyethylene (PE)

or polypropylene (PP) woven fabric are produced

by interweaving polypropylene (PP) or High-Den

sity Polyethylene (HDPE) tapes into fabric, and

they are highly durable and puncture resistant

Advantages/Characteristics of Paper-Poly Bags

Higher strength and durability

Higher strength and durability High puncture/tear resistance

High puncture/tear resistance Higher moisture resistance

Higher moisture resistance All bags can feature anti-skid, Easy Open and Micro Perforations

All bags can feature anti-skid, Easy Open and Micro Perforations Bags are available in gusseted, flat tube, back seam and valve styles

Bags are available in gusseted, flat tube, back seam and valve styles-

Better printing quality on paper vs woven fabrics

Better printing quality on paper vs woven fabrics Graphics can be printed in numerous colors

Graphics can be printed in numerous colors Available in pillow style, flat bottom or block bottom

Available in pillow style, flat bottom or block bottom Ideal for automated bagging systems

Ideal for automated bagging systems

Some of the uses of PP Woven Bags include

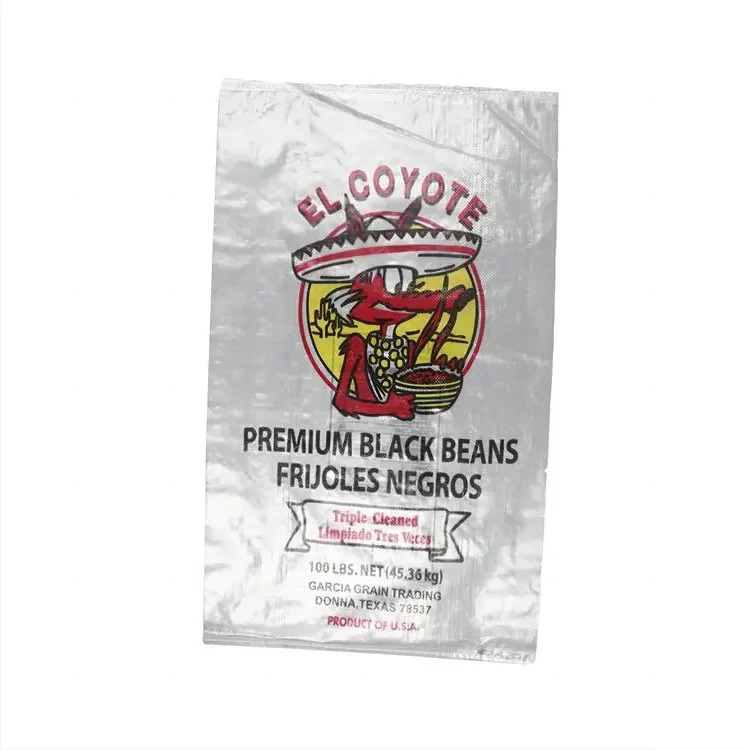

Grains

Grains Seeds

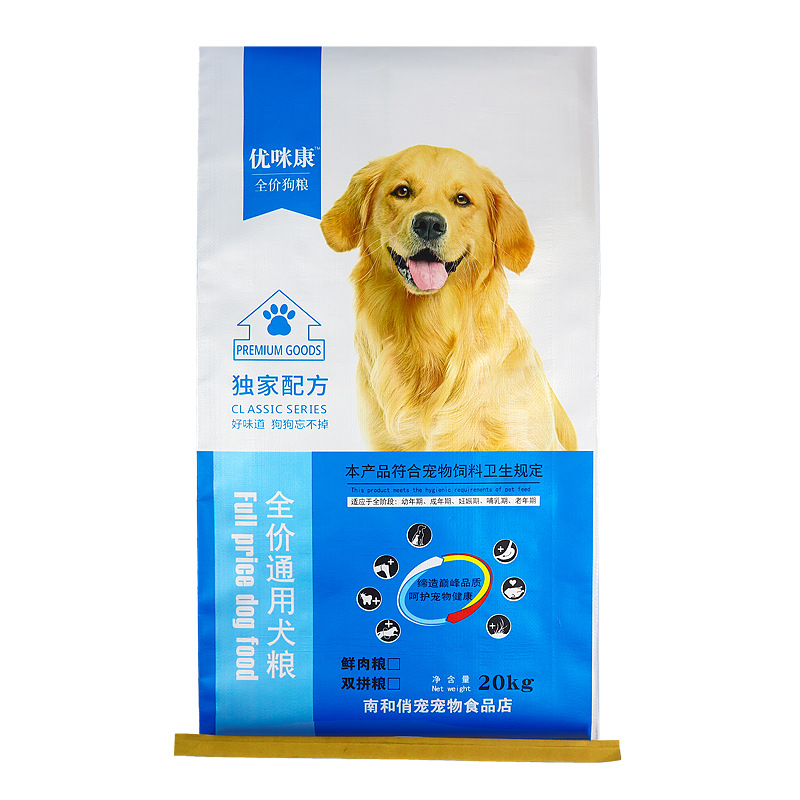

Seeds Pet food

Pet food Flour

Flour Rice

Rice Sugar

Sugar Fertilizers

Fertilizers Frozen products

Frozen products Chemicals

Chemicals Variousbuilding materials

Variousbuilding materials-

Additional Options

Produced with Kraft brown or bleached white paper shell

Produced with Kraft brown or bleached white paper shell Flat tube/pillow, back seam or gusseted

Flat tube/pillow, back seam or gusseted Open mouth or valve

Open mouth or valve Standard or flat bottom

Standard or flat bottom Anti-Skid

Anti-Skid Easy Open

Easy Open Micro-perforations for breathability

Micro-perforations for breathability Paper tape glued over the seams

Paper tape glued over the seams Available in multi-color printing

Available in multi-color printing

Call us today at 86-311-83503878 to find out more about our BOPP line and how you can make your product stand out from the competition!

Send your message to us:

-

Color pp woven bag

-

PP Woven Bag

-

PP woven bag with printing

-

BOPP Laminated PP Woven Bags

-

paper plastic composite bags

-

Block Bottom Valve Type Bags

-

BULK BAGS / FIBC

-

PP woven fabric roll

-

PE Tarp Roll

-

PE Tarpaulin

-

Laminated fabric roll

-

BOPP woven bag with Liner

-

M fold BOPP woven bag

-

PP woven bag with Liner

-

Transparent pp woven bag

-

Laminated pp woven bag