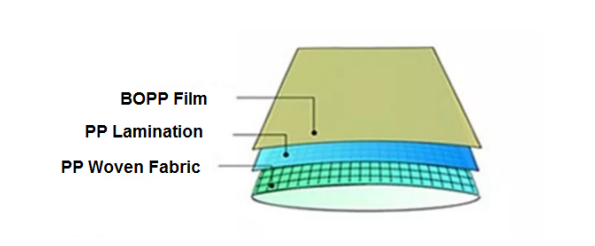

BOPP Laminated PP Woven Bags

Description

BOPP woven bags are made of bopp film, which has the advantages of high transparency, good gloss, good barrier, high impact strength and low temperature resistance. Its overall performance is better than moisture-proof cellophane, polyethylene (PE) film and PET film, so BOPP film also has excellent printing effects.

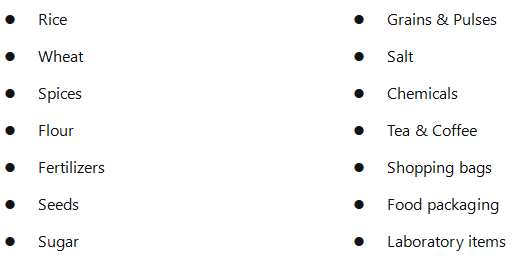

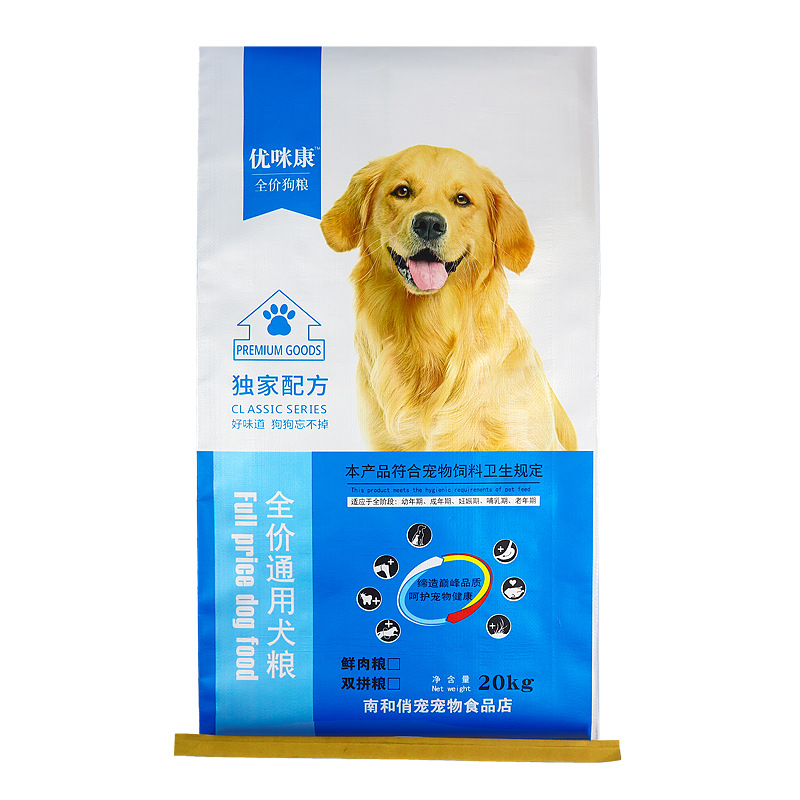

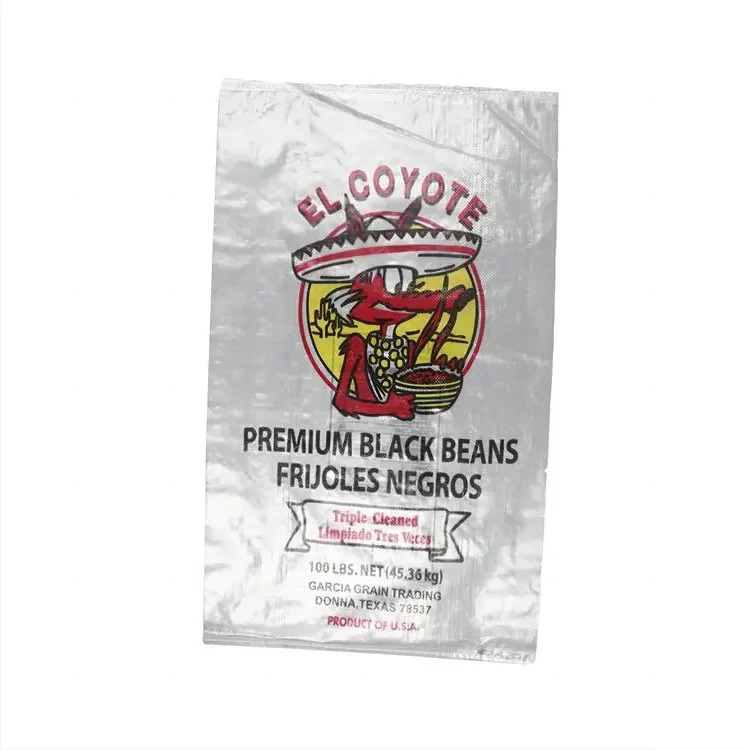

At present, the market mainly uses OPP film, pearl film, matt film and imitation paper film and other colour printing substrates.Usually used for food packaging: rice, flour and other outer packaging. It is also the packaging of grains and cereals to use, plus vivid colour printing patterns, instantly improving the beauty of the product. It can also be used for the packaging of building materials: mortar, putty powder, gypsum powder, etc. BOPP woven bags have become an indispensable element in our daily life, whether in industry, agriculture, chemical industry, etc., they are widely used by us.

Why Choose BOPP Laminated Bags?

BOPP laminated bags stand out as an ideal packaging choice for several reasons:

1.Strength and Durability: BOPP bags are formed by sealing together several components with a layer of polyethylene film. This assembly method results in bags that are sturdy, durable, and easy to handle, making them suitable for bulk shipments.

2.Environmental Impact: In an era of heightened environmental consciousness, BOPP laminated bags shine. Their recyclability and compostable nature contribute to a reduced environmental impact. In response to growing eco-awareness, many jurisdictions mandate the use of BOPP laminated bags for retail packaging, enhancing waste reduction and recycling efforts.

3.Food Packaging: BOPP bags find extensive use in the food industry. They provide a protective barrier against contaminants during shipping and storage, maintaining the freshness and quality of items like frozen foods, meat products, and dairy items. These bags effectively preserve perishable goods at room temperature.

4.Reusable and Versatile: BOPP bags are not only one-time use items. They can be easily washed in warm soapy water and reused multiple times. This makes them an excellent choice for storing cooking ingredients like spices, baking supplies, and condiments, ensuring freshness during trips.

5.Product Visibility: The translucent nature of BOPP bags makes them ideal for showcasing produce, meat cuts, and specialty items. This visibility enhances product presentation while safeguarding their appearance.

Features

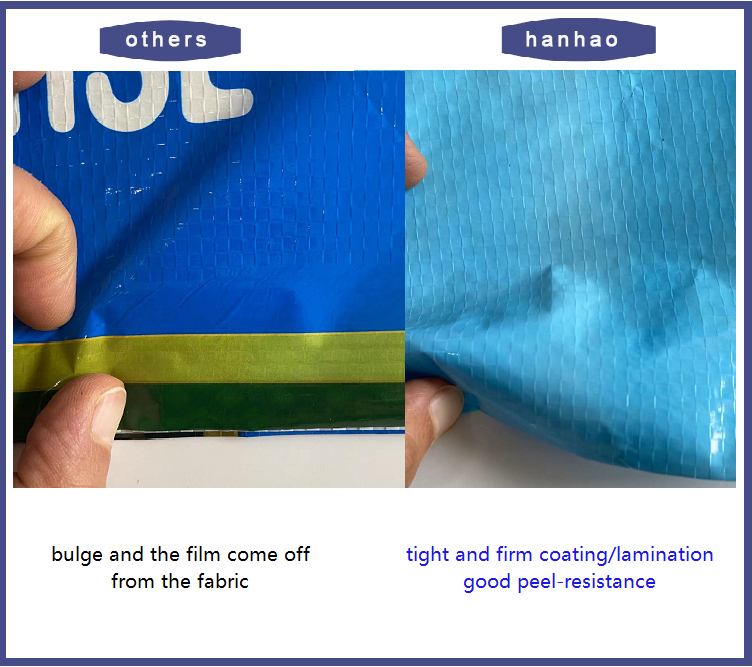

BOPP (bonded on one side) lamination is a technique that involves using heat and pressure to bond multiple sheets of paper together, resulting in a solid and uniform sheet. This type of packaging is particularly favored for various products due to its exceptional qualities. BOPP bags, which are a result of this lamination process, possess the following notable features:

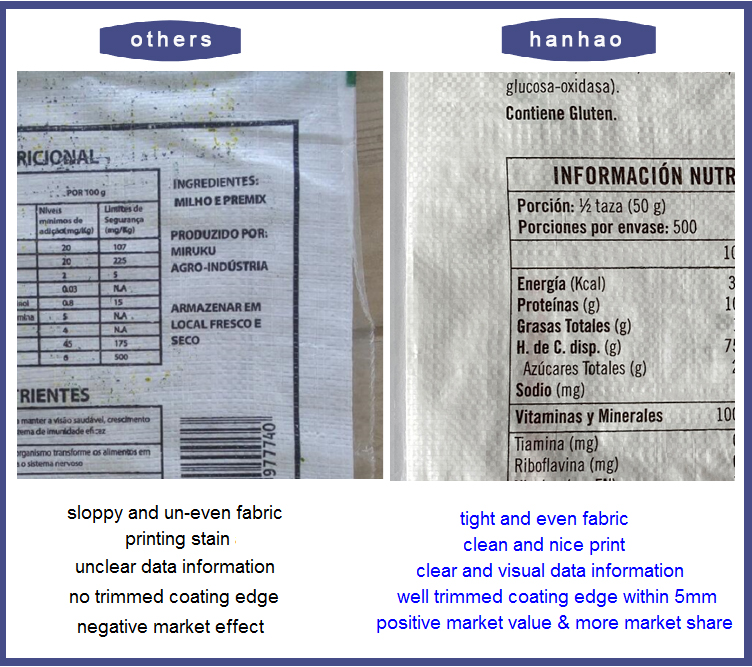

Solid and Uniform: BOPP bags exhibit a sturdy and consistent structure, ensuring the integrity of the packaged items.

Solid and Uniform: BOPP bags exhibit a sturdy and consistent structure, ensuring the integrity of the packaged items.

Ease of Manufacture:The manufacturing process of BOPP bags is straightforward, contributing to their widespread availability.

Ease of Manufacture:The manufacturing process of BOPP bags is straightforward, contributing to their widespread availability.

Cost-Effective: BOPP bags are economically viable, making them a preferred choice for small businesses seeking efficient packaging solutions.

Cost-Effective: BOPP bags are economically viable, making them a preferred choice for small businesses seeking efficient packaging solutions.

High Tensile Strength:These bags offer impressive tensile strength, enhancing their ability to withstand various stresses and loads.

High Tensile Strength:These bags offer impressive tensile strength, enhancing their ability to withstand various stresses and loads.

Excellent Clarity: BOPP bags possess exceptional clarity, allowing the contents to be easily visible.

Excellent Clarity: BOPP bags possess exceptional clarity, allowing the contents to be easily visible.

Low Electrostatic Charge:BOPP bags exhibit minimal electrostatic charge, reducing the potential for static-related issues.

Low Electrostatic Charge:BOPP bags exhibit minimal electrostatic charge, reducing the potential for static-related issues.

Highly Glossy Texture: The bags feature a glossy texture that enhances their visual appeal.

Highly Glossy Texture: The bags feature a glossy texture that enhances their visual appeal.

Stability and Flatness:BOPP bags maintain a high degree of stability and flatness, ensuring consistent presentation.

Stability and Flatness:BOPP bags maintain a high degree of stability and flatness, ensuring consistent presentation.

Waterproof: All BOPP bags are waterproof, protecting the contents from moisture-related damage.

Waterproof: All BOPP bags are waterproof, protecting the contents from moisture-related damage.

Reverse Printing: These bags support reverse printing, offering versatile branding and design options.

Reverse Printing: These bags support reverse printing, offering versatile branding and design options.

High-Speed Printing Performance:BOPP bags excel in high-speed printing scenarios, contributing to efficient production processes.

High-Speed Printing Performance:BOPP bags excel in high-speed printing scenarios, contributing to efficient production processes.

For those experimenting with BOPP lamination, there's room for creativity by exploring different adhesive types and colorants to enhance classic BOPP paper laminated bags.

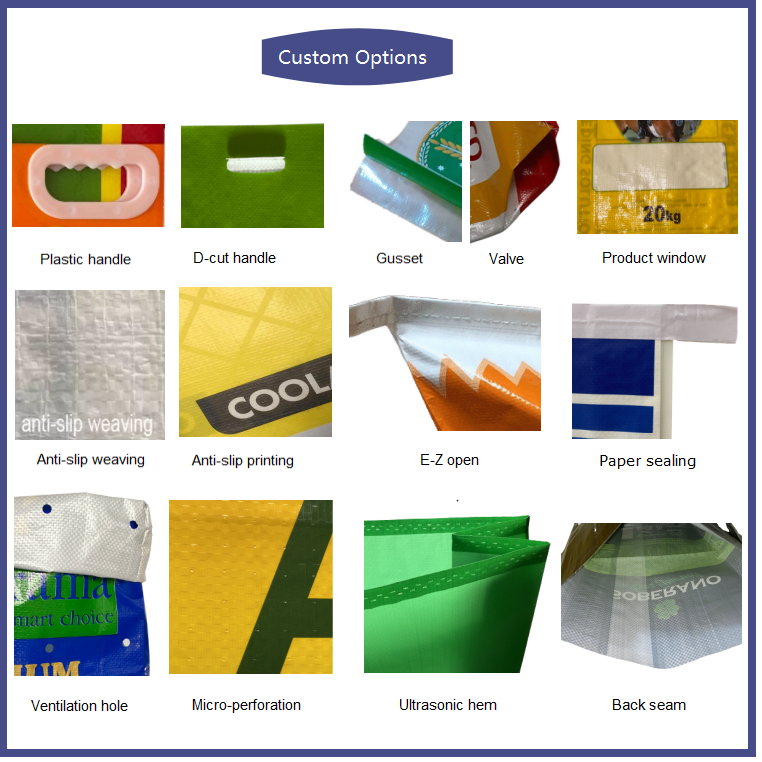

Additional Options

Applications

Our Manufactured BOPP bags are widely used for:

Call us today at 86-311-83503878 to find out more about our BOPP line and how you can make your product stand out from the competition!

Send your message to us:

-

Color pp woven bag

-

PP Woven Bag

-

PP woven bag with printing

-

BOPP Laminated PP Woven Bags

-

paper plastic composite bags

-

Block Bottom Valve Type Bags

-

BULK BAGS / FIBC

-

PP woven fabric roll

-

PE Tarp Roll

-

PE Tarpaulin

-

Laminated fabric roll

-

BOPP woven bag with Liner

-

M fold BOPP woven bag

-

PP woven bag with Liner

-

Transparent pp woven bag

-

Laminated pp woven bag